Smart

Manufacturing

Realized

Rapid ROI through improved profitablity and productivity, for advanced electronics manufacturing operations

Real-time traceability and control for Silicon Photonics, Semiconductor, SMT, System Build, Fiber & Cable manufacturing lines

Low-cost on-premises, cloud or hybrid IT deployments in 3 months or less

Entrusted to drive innovation and scale globally by

Products & Solutions

A complete software and data analytics platform for advanced manufacturing

Direct machine and IIoT data systems integration, automated component inventory traceability, from manual assembly and test, to final customer endpoint

Delivering on the promise of Industry 4.0, Intraratio truly solves the complexities of today’s advanced manufacturing operations

Real time factory monitoring, control and analytics at every level

Rapidly deployed, with near-zero dedicated IT support required

Seamlessly scale from single factory to globally integrated operations

Subscribe to Our Newsletter

Why Choose Intraratio?

Intraratio's smart manufacturing software solutions break the accessibility and integration limitations of existing MES software system

Serialized Traceability

Enforce unit serial and batch traceability, to ensure compliance for highly regulated industries

On Premise, Cloud or Hybrid

Deploy on premise or in the cloud, within your own IT infrastructure for rapid deployment and scale.

Supplier Data Integration

Automate data capture directly from suppliers and contract manufacturers, for extended traceability and quality control.

Manage NPI to High Volume

From prototype to volume, managed in the same system. Seamless change control management for low or high product mix.

Adaptable. Scalable. Data-Driven Automation.

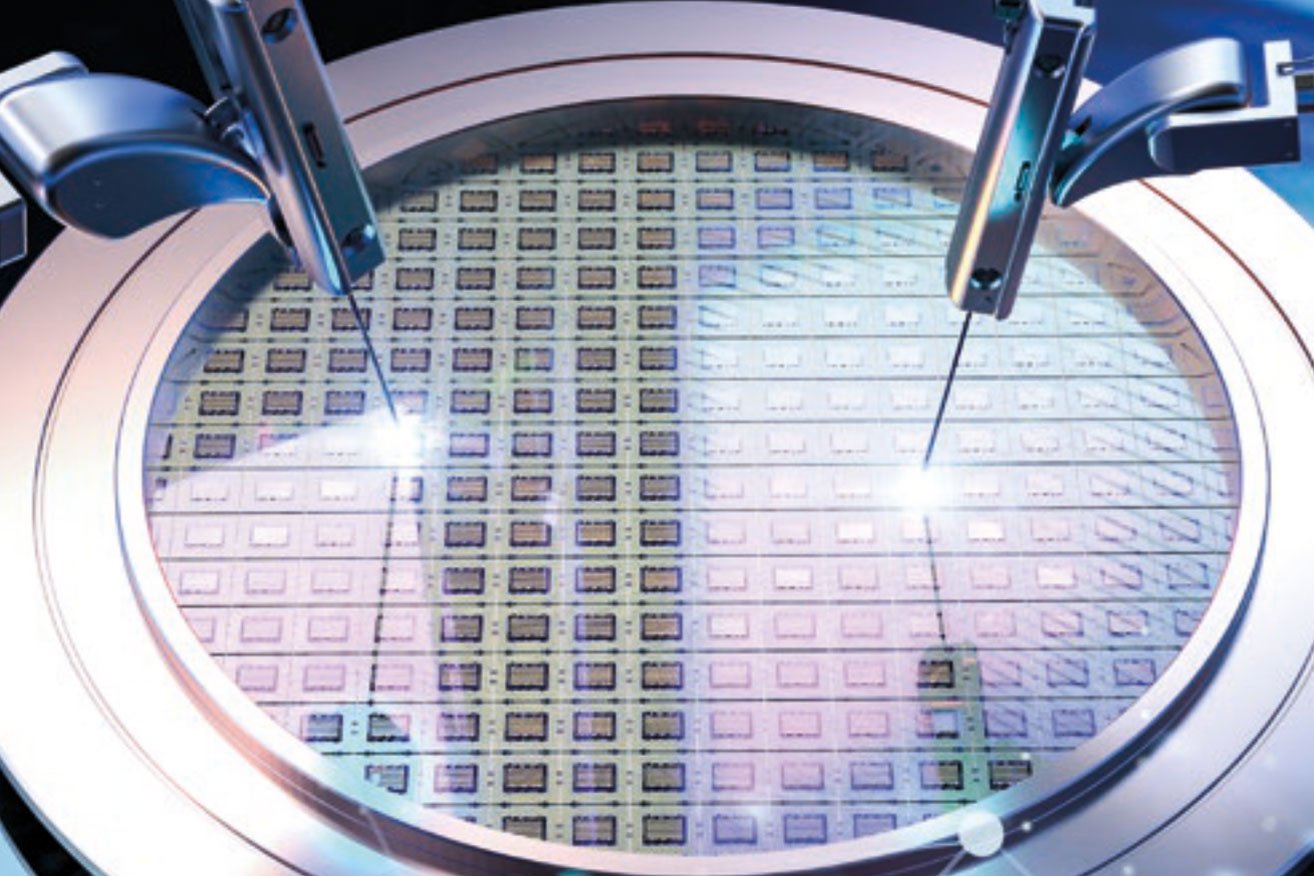

- Deep expertise in test & quality data integration, files parsers and APIs for standard and non-standard tester equipment, including substrate test and KGD mapping

- Our extensive suite of API and open file format parsers enables direct integration capabilities for in-house test platforms and software, for extended scalability and customization where needed

Example integrations:

- Manage inventory, from mobile pick list management, to direct connectivity to storage towers and AGVs

- Directly signal and validate inventory movement from stores to assembly stations

- Provide automated alerts for inventory replenishment, with full inventory consumption traceability and reporting

- We provide the most comprehensive suite of API tools in the industry

- Leverage self-customization and integration on a unified platform, for adaptability and scale to enhance the competitive edge

Web services: REST, SOAP, WebSocket

Data file parsers: XML, JSON, TXT, CSV, STDF, ATDF, PD5, and more

Protocols: SECS/GEM, IPC-HERMES-9852, OpenProtocol, SEMI E142, and more

Step Into Industry 4.0

Intraratio’s solutions communicate directly and indirectly with assembly, test and sensor systems

Automate production and inventory transactions to reduce labor costs and improve quality

Monitor factory operational capacity, utilization and quality in real-time by directly capturing machine state, sensor data, and yield information

Direct From Our Blog

The Costly Risks of Third-Party Machine Data Integrations

Dec 17, 2025

Rethinking MES Integration

Nov 13, 2025

.jpg)