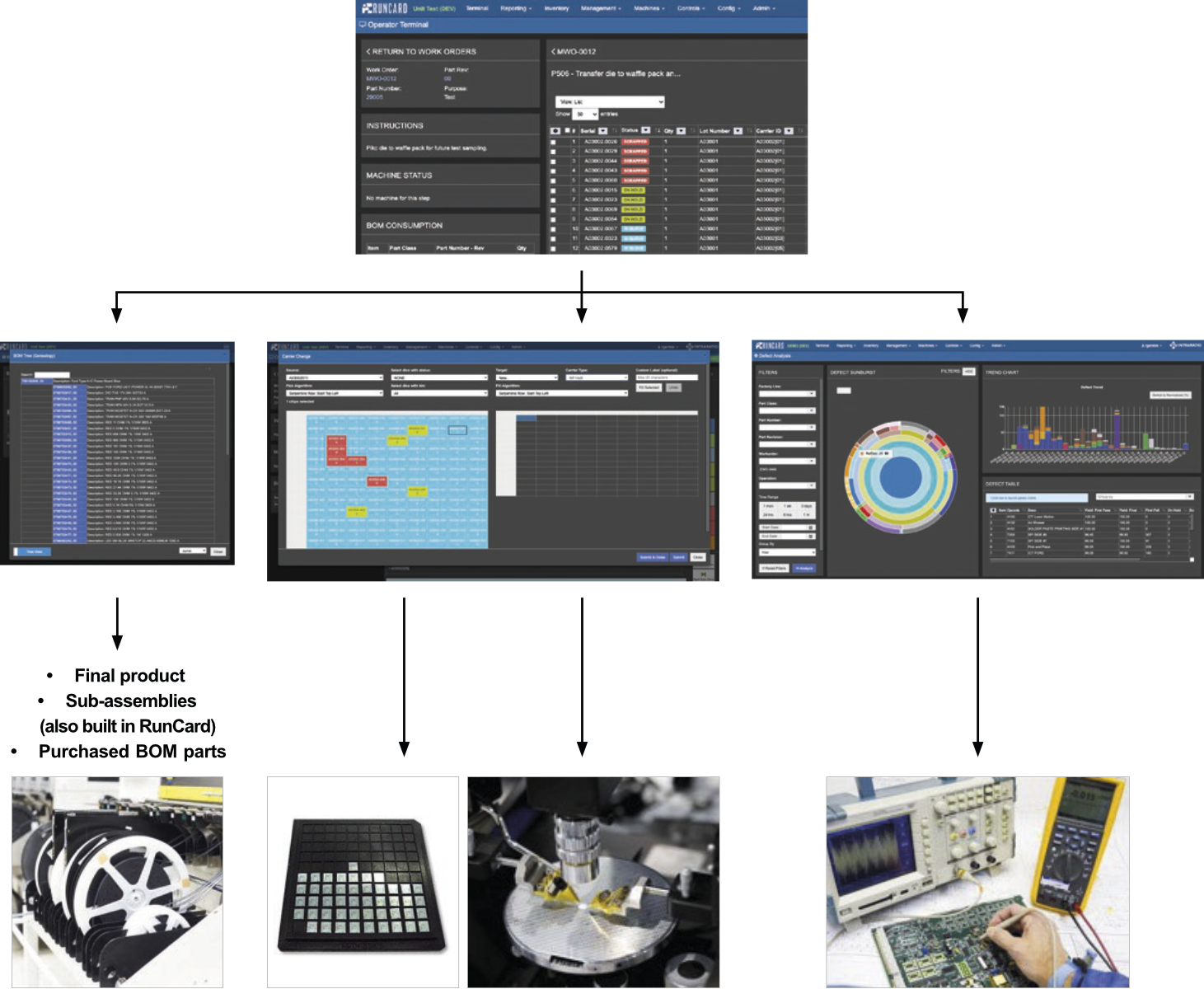

Traceability

Process and Materials to Final Product

Serialized Product Traceability

Product serialization enables manufacturers to track product from initial assembly, through test and delivery, to the end customer

Intraratio's serialization engine generates any format and encoding needed, ensuring no duplicates, with the ability to generate an additional customer and/or supplier-specified serial number as needed

Key benefits & competitive advantages for manufacturers utilizing automated serial number tracking (serialized traceability):

- Improved quality and repair control

- Easier management of warranties and RMA‘s for purchased BOM parts and subassemblies

- Automated monitoring and isolation of defective units

- Reduced risk of human error

- Simplifies regulatory compliance - comply with traceability requirements from highly regulated and quality driven customer verticals (medical, defense and space, automotive)

- Enables AI/ML utilization for automated outlier and failure detection

Inventory Control & Traceability

Inventory receipt scanning, label printing, and quality control can be automated to remove human errors, for better inventory management, traceability and cost (loss) reduction.

Our serialization engine assigns internally unique identifiers per each inventory item, enabling individual-part traceability from supplier to assembly and final product

Avoid costly quality escapes and invalid product loading with automatic alerts, blocking of inventory based on specific rules, and the ability to manage expiration dates, moisture sensitivity levels, FIFO consumption/usage enforcement, and part bins

Synchronize back-office systems, inventory receipts and consumption with direct integration for more accurate cost accounting and procurement

Process & Change Control Management

Advanced product configuration management enables seamless changeover on the line

Leverage production control automation by digitizing processes, for portability of production lines and seamless knowledge transfer

Ensure and simplify compliance for highly regulated industries with release-level management and audit logs

From NPI to high volume, low or high mix, build product the way you need to with a system that adapts to your requirements

Test Yield & Quality Data Analytics

Our solutions provide real-time capture and storage of test, measurement, defect, inspection and quality data

With built-in support for all standard data types and protocols, no third party software is required

Fully contextual data storage enables automated reporting with advanced analytics, and is critical for AI/machine Learning applications

Data source connectivity includes machines, testers, suppliers, sensors and more

Features rich analytics, including parametric trends and distributions, SPC charts, defect and bin paretos, semiconductor wafer and substrate maps, and genealogy trees

-1.png?width=900&height=525&name=Test-Yield-Quality-Analytics%20(1)-1.png)

Planning & Resource Management

Prioritize work orders based on real-time data on capacity utilization, inventory and resource availability, with predictive time-to-deliver

Leverage deep data to drive more accurate demand planning, cycle times and yields across process steps and product groups with varying inventory requirements, coupled with machine utilization metrics

Empowers higher precision planning to address today's supply chain complexities

Semiconductor & MEMS Wafer Analytics

Track today’s most complex chip-level assembly and test processes serving high performance computing, communications, space/military, automotive and medical device industries

Capture data automatically, from inline fab to defect inspection, wafer probe, multi chip-on-chip assembly, to back-end final assembly and test

Leverage a unified platform to manage your data interchange and production visibility needs for complex semiconductor and MEMS-based product manufacturing

User Access

Leverage simple yet powerful user access management and work traceability utilizing encrypted user accounts which allow access to the application, with settings for defining each role

Users can be restricted to certain product lines, as well as to only specific work operations within a product line

Audit logs provide visibility into when users log on and off, while transaction logs capture what work was performed and when

For product, process, and BOM updates, change logs are captured with each update and release, for full audit purposes

-1.png?width=900&height=525&name=User-Access%20(1)-1.png)